Introduction

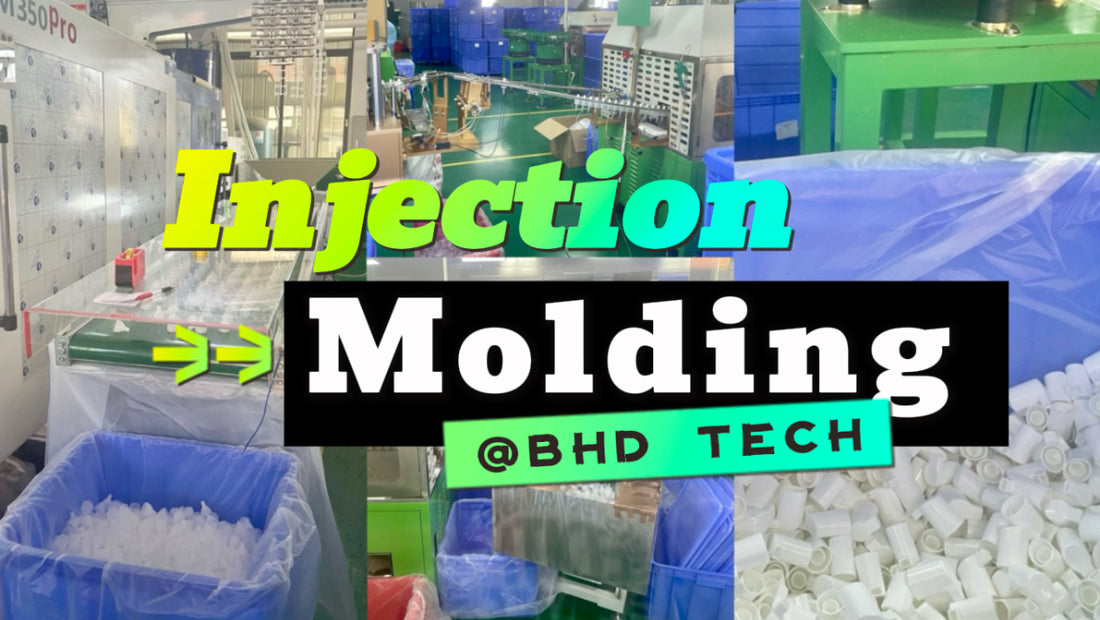

In the world of manufacturing, precision and efficiency are paramount. Whether it's creating intricate components for consumer electronics or crafting sturdy casings for industrial machinery, the injection molding process plays a vital role in turning ideas into tangible products. At BHD Tech, we take pride in offering OEM/ODM custom services that leverage our extensive experience in injection molding. In this article, we will delve into the details of the injection molding process, highlighting each crucial step from raw material preparation to the final product, while also showcasing our commitment to tailor-made solutions.

1. Raw Material Preparation

The journey of creating a high-quality injection-molded product begins with the careful selection and preparation of raw materials. At BHD Tech, we understand the significance of choosing the right materials to meet our clients' unique specifications.

a. Material Selection: The choice of material depends on factors such as product functionality, durability, and appearance. Common materials include thermoplastics, thermosetting plastics, and elastomers. We work closely with our clients to determine the best material for their specific needs.

b. Material Drying: Moisture can negatively impact the injection molding process, causing defects in the final product. To mitigate this risk, we ensure that the selected materials are properly dried before use, maintaining their integrity during the molding process.

2. Melting Plastic

Once the materials are prepared, the next step in the injection molding process is melting the plastic. This process involves raising the temperature of the raw material to its melting point, transforming it into a molten state for molding.

a. Hopper: Raw materials are loaded into a hopper, which feeds the material into the molding machine's barrel.

b. Barrel and Screw: Within the barrel, a screw mechanism helps melt and mix the material thoroughly. The heat generated by the barrel ensures the plastic is in a molten state, ready for injection.

3. Injection Molding

The heart of the injection molding process is the actual injection into the mold cavity. This step requires precision and control to create the desired product.

a. Mold Design: At BHD Tech, we collaborate closely with our clients to design molds that meet their specifications. Our state-of-the-art design capabilities ensure the utmost precision in molding.

b. Injection: The molten plastic is injected into the mold cavity under high pressure. This process fills every nook and cranny of the mold, ensuring uniformity and consistency.

4. Cooling and Solidification

After injection, the mold must cool down to solidify the plastic and form the desired shape. Proper cooling is essential to prevent warping and defects in the final product.

a. Cooling System: Our production line incorporates advanced cooling systems that control the temperature of the mold. This precise cooling process guarantees the structural integrity and quality of the finished product.

5. Release Mold

Once the plastic has cooled and solidified, the mold is opened, and the newly formed part is released. This is a critical step in the process, as it must be executed with care to prevent damage to the part or the mold.

a. Ejection: The mold's ejector pins push the part out of the cavity, ensuring a smooth and consistent release.

b. Inspection: Quality control is a top priority at BHD Tech. We thoroughly inspect each molded part to ensure it meets the client's specifications and our high standards of quality.

BHD Tech's OEM/ODM Customization Service:

Our commitment to excellence extends beyond the injection molding process itself. At BHD Tech, we offer comprehensive OEM/ODM customization services to meet the unique needs of our clients.

-

Design Collaboration: We work closely with our clients from the initial concept to the final design, ensuring that the end product perfectly aligns with their vision.

-

Material Expertise: With years of experience, we provide expert guidance on material selection to optimize product performance and cost-efficiency.

-

Prototyping: We offer prototyping services to validate designs and functionalities before mass production, saving time and resources.

-

Precision Molding: Our state-of-the-art injection molding capabilities guarantee the utmost precision and consistency in every product we manufacture.

-

Quality Assurance: Rigorous quality control measures ensure that each product meets the highest industry standards.

Conclusion

The injection molding process is a multifaceted journey that transforms raw materials into high-quality products. At BHD Tech, our dedication to excellence shines through every step, from material selection and melting plastic to injection molding, cooling, and mold release. Our commitment to OEM/ODM customization services allows us to cater to the unique needs of our clients, ensuring that their visions become reality. When it comes to injection molding, trust BHD Tech to deliver precision, efficiency, and quality in every project. Contact us today to explore how we can bring your ideas to life through our expert injection molding services.